|

- 品牌:Qnity

- 型号:卷

- 价格: ¥137/盒

- 发布日期: 2025-11-28

- 更新日期: 2026-02-26

| 品牌 | Qnity |

| 货号 | |

| 用途 | 航空航天 |

| 牌号 | PI Kapton 150MT PLS |

| 型号 | Kapton 150MT PLS |

| 品名 | PI |

| 包装规格 | 卷 |

| 外形尺寸 | 薄膜 |

| 厂家 | Qnity(Dupont 杜邦) |

| 是否进口 |

从航天任务相机中的电路到下一代光伏电池,Kapton®聚酰亚胺薄膜正在推动非凡的新设计可能性真正实现。

对于 热量和振动的应用,设计师依赖Kapton®,因为它能够在最恶劣的条件下保持独特的机械性能组合。

Kapton®聚酰亚胺薄膜在45年来一直保持行业标准,在高性能、可靠性和耐用性方面保持着标准,具有独特的电气、热能、化学和机械性能组合,能够承受 温度、振动及其他严苛环境。

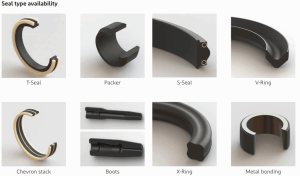

使用杜邦™ Kapton® 进行成型

6. 成型模具

迄今为止,杜邦的薄膜成型测试均使用单模进行。

然而,经验表明,多级模具效率更高,效果更佳。

使用多级模具,可以显著改善零件的复杂性和延伸率。

为获得 效果,建议使用两到三个深度递增、零件轮廓逐渐清晰的模具。

多个模具还有助于控制薄膜的变薄和应力。

阶段: 个模具用于制作大致形状;该形状略大且轮廓模糊。 步是将所需的薄膜拉入工作区域。

由于零件尺寸较大,因此会拉入足够的薄膜以缓解大部分材料应力和变薄。

在此步骤中,尤其要注意褶皱(使用薄膜时始终存在褶皱的可能性)。如果在成型初期阶段出现皱纹,则成品零件中也会存在皱纹。后续加工步骤无法去除这些皱纹。

阶段: 个(也可能是 一个)模具步骤用于将薄膜成形到下一个阶段。根据零件的最终深度和形状,可能不需要额外的模具。

个和第三个模具应将零件的清晰度提高 10% 到 30%。这是通过评估零件的复杂性和总深度来确定的。

第三阶段: 阶段的延续,用于更深、更复杂的零件。

三阶段成型示例

测试表明,Kapton® 薄膜可以很好地复制模具形状。杜邦测试中使用的模具是匹配的金属模具。

下模为阴模且固定。上模为阳模,并连接到冲头(间隙为薄膜厚度:±0.0002)。这种方法对浅深度零件非常有效。

对于深拉延零件,可能需要调整阴阳模的位置,以便进行推进。成形浅深度零件时,阴模位于底部效果很好;但对于深拉延零件,阴模位于顶部可能更合适。如果零件是真正的深拉延零件,则应考虑使用阴阳模可伸缩式模具。

由于模具的公差很小,成型零件的脱模有时会成为一个问题。这个问题与模具打开时产生的真空有关。真空除了会将零件固定到位外,还会导致起皱。一种解决方法是设置一个脱模口(阴模上的一个小孔,允许空气进入)。

这个孔应该足够小,以免在零件上留下痕迹。其他可能的解决方案包括喷砂处理、使用哑光模具,以及在模具上切割非常小的凹槽。

如果零件包含 90 度弯折,则需要进行半径切割(最小半径为 0.03125 英寸)以防止撕裂。成品零件的形状和拉伸程度将决定该半径是否足够。如果需要更大的半径,则应根据实际情况确定。

注意:在某些情况下,可能需要辅助零件从模具中取出(通常在侧壁为 90 度或拉伸程度较大时)。少量气流通常可以提供帮助。

在为模具材料选择金属时,请记住成型操作的温度范围为从环境温度到 750°F (400°C)。

应选择在此温度范围内尺寸稳定的金属。杜邦的实验室模具由铝和工具钢制成。

成型唇是底模上凸起的部分,用于帮助拉伸薄膜。该凸缘的高度应至少为 60 密耳,至多为 75 密耳(适用于 3 密耳和 5 密耳的薄膜)。如果凸缘过短,则无法充分拉伸薄膜以消除皱纹(薄膜松弛会在受压时产生皱纹)。如果凸缘过高,则薄膜在拉伸时会撕裂。

迄今为止,针对该凸缘直径的合适尺寸,已进行的测试有限。对于浅拉伸零件,凸缘只需略大于零件本身(10 至 20 密耳)。对于更复杂的形状,数据表明,直径应基于成品零件的复杂性和深度。无论如何,凸缘的直径应比压板开口小 50 至 100 密耳。

上模上的台阶为压板提供间隙。该台阶的直径应比压板开口小 0.125 英寸。步长应为 0.500 + 0.015652 英寸,高度为 -0 英寸(基于压力垫厚度)。

Kapton is a polyimide film used in flexible printed circuits (flexible electronics) and space blankets, which are used on spacecraft, satellites, and various space instruments. Invented by the DuPont Corporation in the 1960s, Kapton remains stable across a wide range of temperatures, from 4 to 673 K (?269 to +400 °C). Kapton is used in electronics manufacturing and space applications, with x-ray equipment, and in 3D printing applications. Its favorable thermal properties and outgassing characteristics result in its regular use in cryogenic applications and in high vacuum environments.

History

Kapton was invented by DuPont in the 1960s. As of November 2025, Kapton is manufactured by Qnity Electronics, a spinoff of DuPont.

The name Kapton is a registered trademark of E. I. du Pont de Nemours and Company.

Chemistry and variants

Kapton synthesis is an example of the use of a dianhydride in step polymerization. The intermediate polymer, known as a poly(amic acid), is soluble because of strong hydrogen bonds to the polar solvents usually employed in the reaction. The ring closure is carried out at high temperatures of 470–570 K (200–300 °C).

The chemical name for Kapton K and HN is poly (4,4'-oxydiphenylene-pyromellitimide). It is produced from the condensation of pyromellitic dianhydride (PMDA) and 4,4'-oxydiphenylamine (ODA).

Kapton E is a mix of two dianhydrides, PMDA and biphenyltetracarboxylic acid dianhydride (BPDA), and two diamines, ODA and p-phenylenediamine (PPD). The BPDA component adds greater dimensional stability and flatness in flexible circuitry applications. Kapton E offers reduced coefficient of thermal expansion (CTE), reduced moisture absorption, and reduced coefficient of hygroscopic expansion (CHE) compared to Kapton H.

Characteristics

In isolation, Kapton remains stable across a wide range of temperatures, from 4 to 673 K (?269 to +400 °C).[5][6]

The thermal conductivity of Kapton at temperatures from 0.5 to 5 Kelvin is rather high for such low temperatures, κ = 4.638×10?3 T0.5678 W·m?1·K?1.

Kapton insulation ages poorly: an FAA study shows degradation in hot, humid environments[8] or in the presence of seawater. It was found to have very poor resistance to mechanical wear, mainly abrasion within cable harnesses due to aircraft movement. Many aircraft models have had to undergo extensive rewiring modifications—sometimes completely replacing all the Kapton-insulated wiring—because of short circuits caused by the faulty insulation. Kapton-wire degradation and chafing due to vibration and heat has been implicated in multiple crashes of both fixed wing and rotary wing aircraft, with loss of life. The New York Times, citing a NASA OIG document, reported in 2005 that Kapton-insulated cables on the Space Shuttle "tended to break down over time, causing short circuits and, potentially, fires." The STS-93 mission saw electrical shorts on Kapton insulation disable two engine controllers and nearly cause catastrophe.

Usage

Kapton tapes, three rolls of different widths

Electronics manufacturing

Kapton tape (yellow) used to insulate the leads of a battery cell in a bluetooth headset

Due to its large range of temperature stability and its electrical isolation ability, Kapton tape is usually used in electronic manufacturing as an insulation and protection layer on electrostatic-sensitive and fragile components. As it can sustain the temperature needed for a reflow soldering operation, its protection is available throughout the whole production process, and Kapton is often still present in the final consumer product.

Spacecraft

Aluminized Kapton thermal cover was used on the Ultra Heavy Cosmic Ray Experiment.

The descent stage of the Apollo Lunar Module, and the bottom of the ascent stage surrounding the ascent engine, were covered in blankets of aluminized Kapton foil to provide thermal insulation. During the return journey from the Moon, Apollo 11 astronaut Neil Armstrong commented that during the launch of the Lunar Module Eagle ascent stage, he could see "Kapton and other parts of the LM staging scattering all around the area for great distances."

Test unit of the James Webb Space Telescope sunshield, made of aluminized Kapton

The NASA Jet Propulsion Laboratory has considered Kapton as a good plastic support for solar sails because of its durability in the space environment.

NASA's New Horizons spacecraft used Kapton in an innovative "Thermos bottle" insulation design to keep the craft operating between 283 and 303 K (10 and 30 °C) throughout its more than nine-year, 5-terametre (33-astronomical-unit) journey to rendezvous with the dwarf planet Pluto on 14 July 2015. The main body is covered in lightweight, gold-colored, multilayered thermal insulation which holds in heat from operating electronics to keep the spacecraft warm. The thermal blanketing of 18 layers of Dacron mesh cloth sandwiched between aluminized Mylar and Kapton film also helped to protect the craft from micrometeorites.

The James Webb Space Telescope sunshield is made of five Kapton E sheets coated with aluminum and doped silicon to reflect heat away from the spacecraft body.

The crew aboard the International Space Station used Kapton tape to temporarily repair a slow leak in a Soyuz spacecraft attached to the Russian segment of the orbital complex in August 2018.[16] It was used again in October 2020 to temporarily seal a leak in the transfer chamber of the Zvezda Service Module of the ISS.

X-rays

Kapton is also commonly used as a material for windows used with all kinds of X-ray sources (synchrotron beam-lines and X-ray tubes) and X-ray detectors. Its high mechanical and thermal stability as well as high transmittance of X-rays make it the preferred material. It is also relatively insensitive to radiation damage.

3D printing

Kapton and ABS adhere to each other very well, which has led to widespread use of Kapton as a build surface for 3D printers. Kapton is laid down on a flat surface and the ABS is extruded onto the Kapton surface. The ABS part being printed will not detach from the build platform as it cools and shrinks, a common cause of print failure by warping of the part.A more durable alternative is to use a polyetherimide surface.

Researchers have devised a method to 3D-print polyimide material including Kapton. The polyamic acid precursor to Kapton is mixed with an acrylate cross linker and photoinitiator that can form a gel when exposed to ultraviolet light during 3D printing. Subsequent heating of the 3D printed part up to 400 °C removes the sacrificial crosslinks and imidizes the part forming Kapton with a 4D printed geometry.

Others

Kapton's relatively high thermal conductivity at very low temperatures, together with its good dielectric qualities and its availability as thin sheets, have made it a favorite material in cryogenics, as it provides electrical insulation at low thermal gradients.

Kapton is regularly used as an insulator in ultra-high-vacuum environments due to its low outgassing rate.

Kapton-insulated electrical wiring has been widely used in civil and military aircraft because it is lighter than other insulators and has good insulating and temperature characteristics.